As far as I am aware Derann had always sold it’s product in some sort of packaging. White cardboard boxes (200′ and 400′), abound in every corner and there were regular deliveries of these when I joined in 1975. They were packaged not only because they protected the film, but also because the film was easier to store on the shelves both in the shop and the small ‘stock room’. There were only a few titles that had their own labels, in most cases the title would be typed onto self adhesive labels and stuck onto the spine of the box, or the part one box if it was a feature, with the other parts rubber stamped with the part number or applied from a roll of sticky backed pre-printed numbers, whichever was nearest to hand.

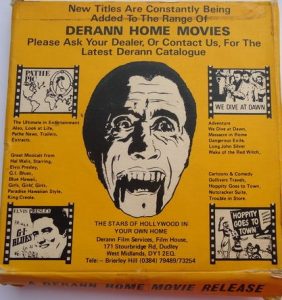

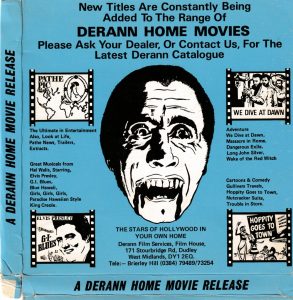

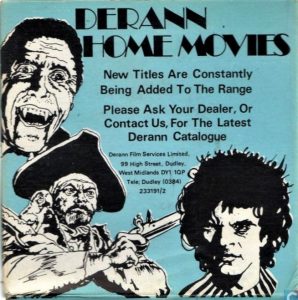

By the middle of the following year the white card boxes were given a yellow colour wash and ‘A Derann Home Movie Release’ was proudly printed on the side spines and a hand drawn advert featuring Christopher Lee as ‘Dracula’ was on the reverse, by 1977 it was a blue wash and 12 months later a newly designed reverse was revealed, along with our new address. The later one was probably designed by Marianne Frost, who was becoming our regular artist for all our 8mm releases an later the video cassettes.

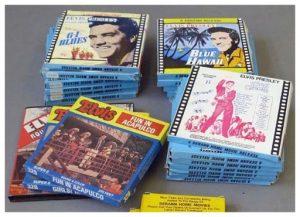

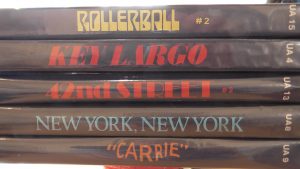

Both Derek and I had always been impressed with the plastic packaging that the German super 8 companies, UFA, Piccolo and Marketing Film were using and when we were granted the prestigious rights to some of the Warner Brothers classics it was decided that we would invest in the ‘new’ plastic clamshell packaging. This was one of the factors that helped us in being able to obtain the films, as UA were more than a little impressed with the idea of the plastic packaging. We found a local based plastics vacuum forming manufacturer that could produce the moulded cases and they were asked to produce samples which included the DFS logo on the inside. It took some time for them to produce the mould itself and after a few attempts they appeared to be ready, but problems followed such as the plastic being so ridged that they refused to bend and clamp shut. When they eventually began to produce them we then supplied the labels, which would then be incorporated into the finished case. There was a minimum number on orders placed for any title, so the storage of the cases themselves became somewhat of a problem, which we overcame by turning the, as yet, unused attic section of 99 High Street, into a storage area for them. But even these early cases proved to brittle and didn’t travel well, so it was back to the drawing board and new plastic compounds were tried and new colours, until we were happy! The final piece of this tale is the shrink wrap that kept the feature parts together and the clam shell cases shut, it made them look very professional. It was an arduous task each film first being encased in the wrap, before being trimmed and sealed, then placed on a conveyer belt that went through a heated tunnel which ‘shrunk’ the clear film. The final two pictures accompanying this post are of a roll of shrink wrap and the machine that did the job…. our machine was in two parts, not as modern as the one in the final photo. When we presented our product at the “Home Screen Scene ’80” held at the Rembrandt Hotel, these cases where prominently displayed for the first time and Ralph Gill of P.M. Films came along and loudly proclaimed they were a waste of money, to which I responded “**** *** Ralph!!”. Yes I was very proud of our new packaging and rightly so.

Leave a Reply